1. Processing of Fresh Fruit

Select the poor quality fruit, then put the fruit into the brush cleaner for cleaning, then enter the crusher for

Throwing Knife crushing to form small pieces of pulp, then go into the juicer to squeeze the pulp, and

separate the core, peel and fiber.

2. Mixing and Ration

According to the prepared formula table, a certain proportion of water, sugar and other food additives shall

be added quantitatively.

3. Homogenization and Sterilization

The fruit juice is broken and refined under high pressure, so that the final fruit juice products with long shelf life

are not easy to precipitate, thus affecting the taste. Then, the fruit juice was subjected to ultra-high temperature

instantaneous sterilization, make it free of any bacteria to extend the shelf life. The whole process is carried out

inside the machine, and the fruit juice is not in direct contact with the heating medium. Instead, the plate heat

exchanger or bellows heat exchanger is used for indirect heat exchange, ensuring that the quality of fruit juice

products is not polluted.

4.Filling and Packaging

The freshly sterilized fruit juice directly enters the hot filling machine and is quantitatively filled into the package

by the precise filling head, so that it can still maintain high temperature during the filling period to prevent the

breeding of bacteria. Then, it is transported to the labeling machine for automatic labeling and printing date,

and packed and packed.

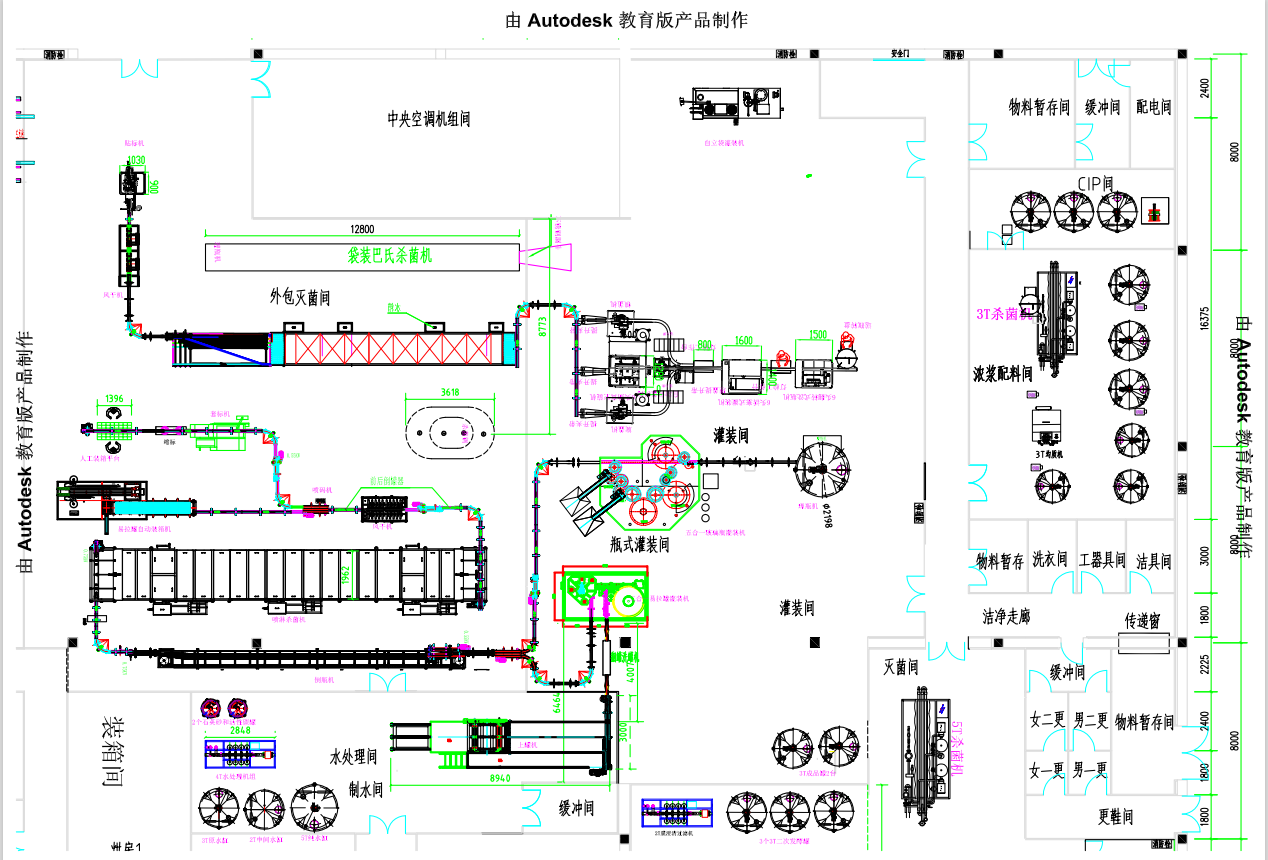

Remark: Our company can provide turnkey projects such as equipment production, equipment installation and

commissioning, equipment use training, factory layout design, juice formula configuration, etc. If there are any

questions or demand, please feel free to contact us, we will do our best to help you!